Custom Services

Main Production Process

Our company has an independent and powerful R&D team and mold production workshop, independent research and development at the same time to undertake mold processing business.

In addition, we have several supporting workshops for products from raw materials to finished products, such as cold heading, finishing, forming, etc., which integrates multiple processes into one, eliminating multiple links in the middle and giving profits to customers.

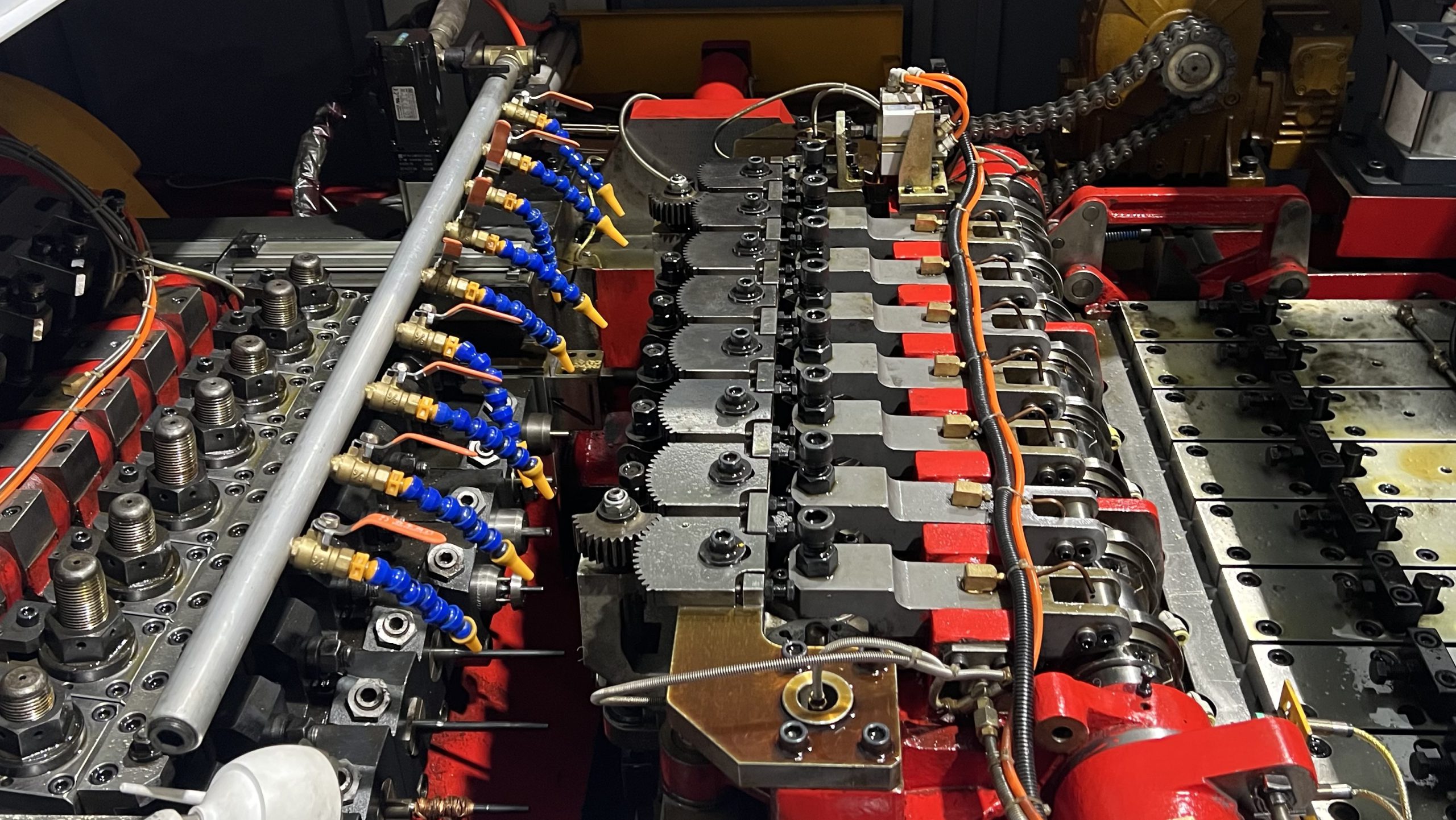

Automatic Multi-station

Cold Forming Machine

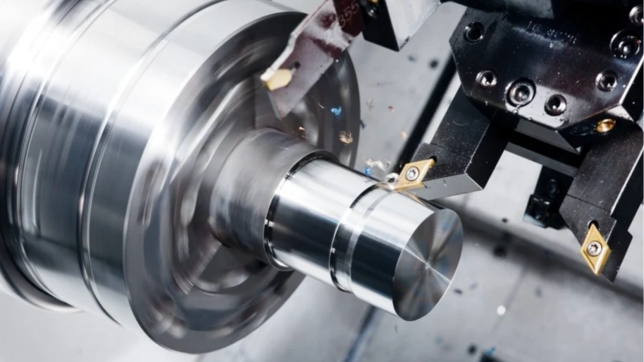

CNC Machining Center

Stamping Machine

Production Deformation Process

Material preparation

Select suitable metal wire or rod, then cut it into blanks according to required lengths.

Upsetting

Place the blank in a die, and a punch applies pressure to shorten the blank’s length and increase its diameter.

Heading

The punch continues to shape the top of the workpiece into the desired head form.

Extrusion

Force the material through a die opening to create specific cross – sectional shapes when necessary.

Trimming and finishing

Trim off excess material, and then conduct operations like polishing, deburring, and heat treatment.

Why us?

This is some dummy copy. You’re not really

supposed to read this dummy copy.

→

Development Capability

We have professional R&D team, quality control personnel and mature hardware processing technology

Process Design Capability

Good process design capability can reduce production costs

Manufacturing Capability

Our equipment can produce efficiently, on time and with quality

Quality Control

Each production process has strict technological requirements, all departments cooperate with each other, strictly control each part of production, to achieve efficient and high quality delivery. Now we has a group of professional foreign trade team which to provide good service.

Geographical Position

We are located in Yinzhou District which is the largest manufacturing center of Ningbo and less than 50km away from the world’s fourth largest port — Ningbo Beilun Port. In this way we can deliver goods promptly and quickly.

Testing Equipment

These devices can detect the angle, concentricity, hardness, surface finish, appearance, product resistance, heat treatment hardness and other parameters of metal products, and can be used to deetect possible defects or impurities in metal products. To ensure that product quality meets the standard requirements, help us improve product quality and production efficiency, and ensure product safety