Reliable

Custom Fastener

Solutions

Understand the needs of customers, improve diligently, and strive to

provide customers with a complete set of fastener customization solutions.

Provide High – Quality

Custom Fastener Solutions

And Strict Quality Control

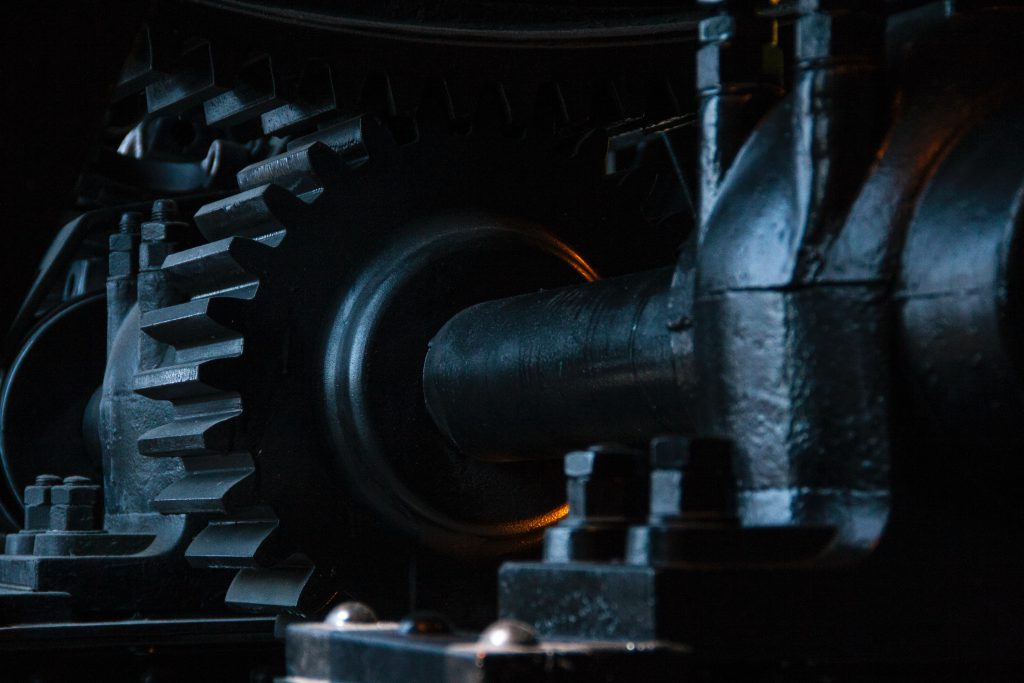

As a leading manufacturer of custom fasteners, our seasoned team combines unrivaled customization capabilities with a stringent quality control system to offer comprehensive and reliable custom fastener solutions. In the fastener industry, off – the – shelf products often fall short in meeting the diverse and complex requirements of various applications. We, as a professional custom fastener manufacturer, center around our outstanding team to present you with unparalleled custom fastener solutions.

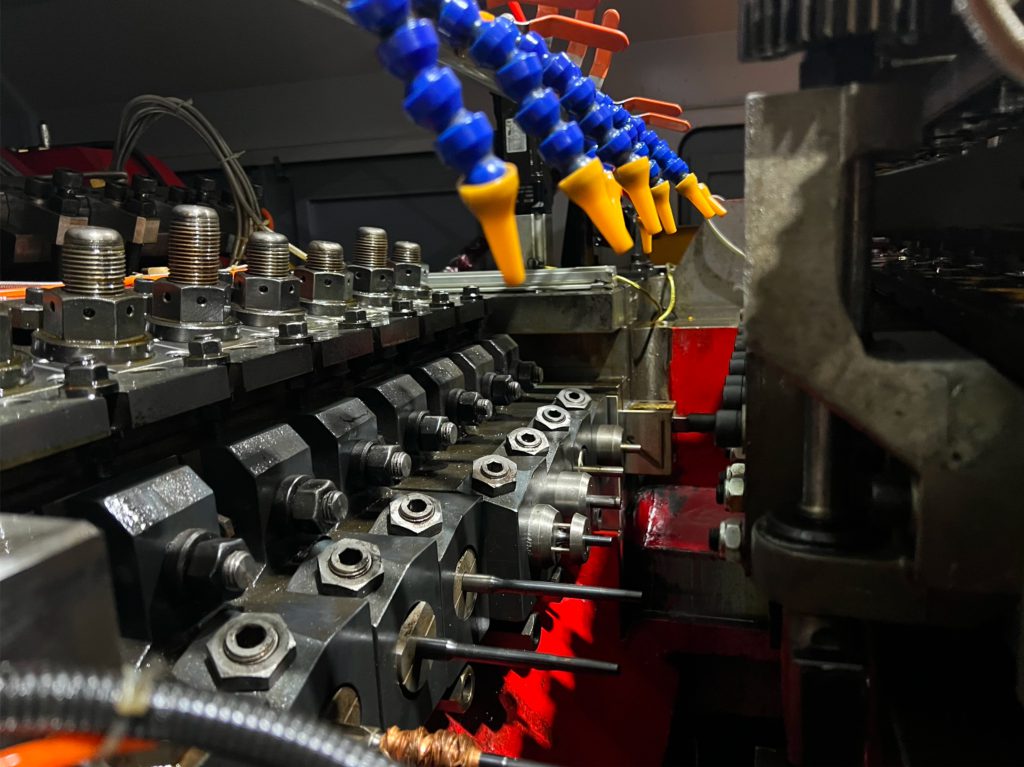

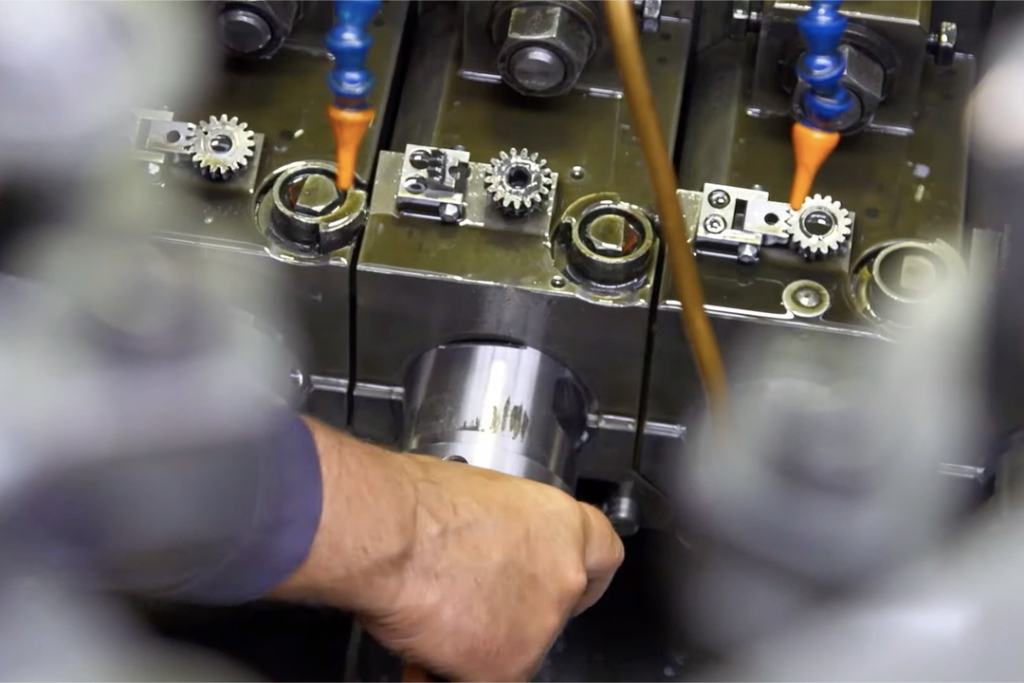

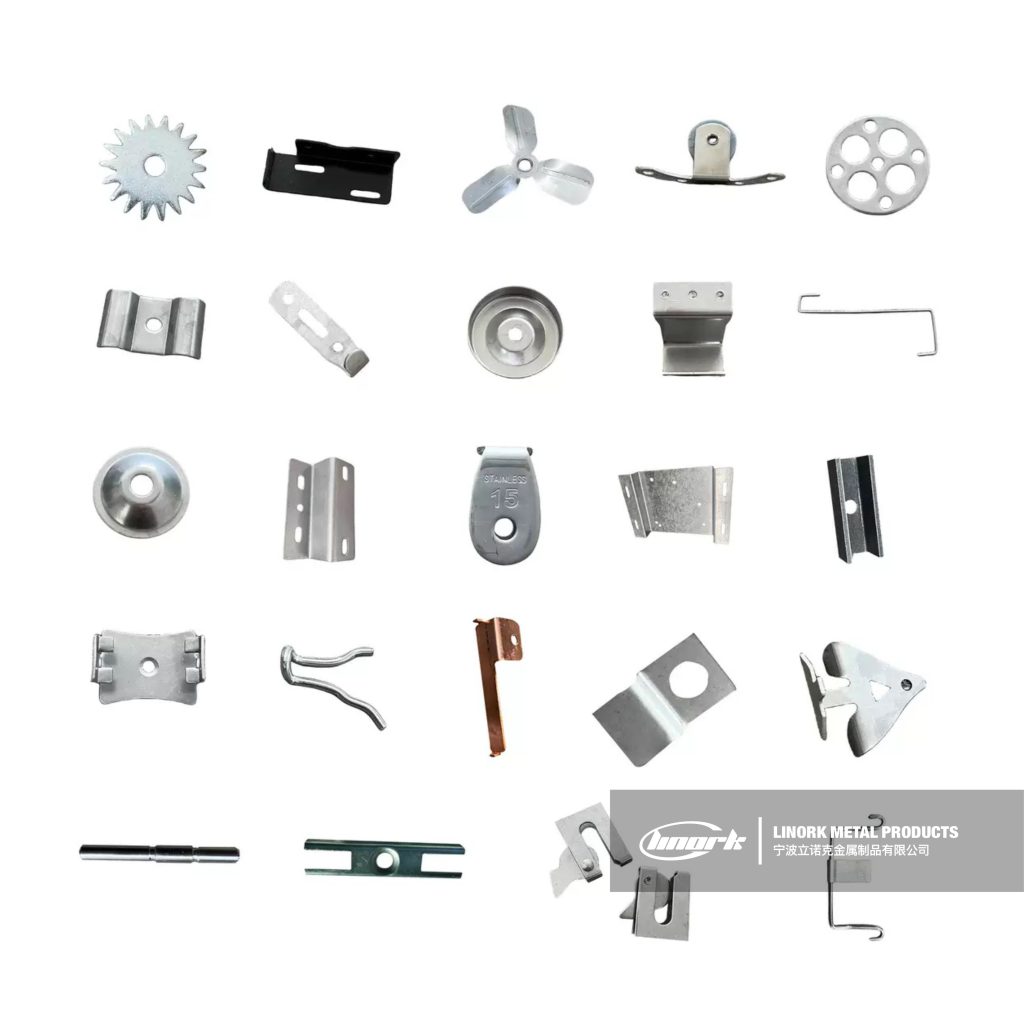

Metal Forming

Metal forming is a widely used manufacturing process that involves applying force and pressure to metal materials to change their shape, size, and properties. Cold heading, stamping, and CNC machining are three common processes in metal forming

20+

Years Experience

50+

Automation Equipments

99%

Customer Satisfaction

24h

Efficient Service

Efficient Services

We are a professional factory specialized in the production of custom precision hardware parts. Our products include bolts, screws, shafts, nuts, tool accessories, and other items in various specifications and shapes. We use advanced cold heading processing technology to produce high-precision, high-strength cold heading parts, which are widely used in mechanical tools, furniture accessories, automotive components, and the construction industry. With advanced production equipment and a technical team, we can provide customized products and solutions according to customer needs.

Customized Service

We have strong customization capabilities, allowing us to customize various fastener products according to customer’s specific requirements. This includes customizing dimensions, materials, surface treatments, and other specifications based on customer needs. We may also offer customized packaging and labeling options to meet customer’s branding or logistical requirements. These customization capabilities enable us to provide solutions that meet the unique needs of customers in various industries.

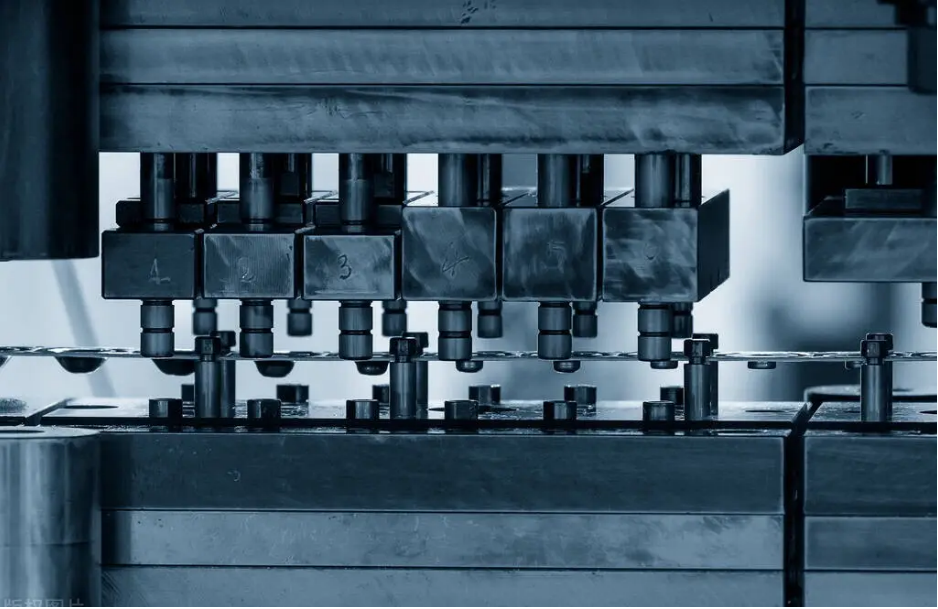

Process Design

We have excellent process design capabilities. This includes determining the best production methods, process routes, and process parameters to ensure the production of high-quality products that meet customer requirements. Excellent process design capabilities can help us improve production efficiency, reduce production costs, and ensure stable and reliable product quality. Strict quality control ensures that products meet customer requirements and standards.

Quality Control

We have strong quality control capabilities to ensure that our products meet customer standards. This includes thorough material inspections, precise manufacturing processes, and comprehensive inspection procedures. Linork adheres to international quality standards such as ISO 9001/IATF 16949 to demonstrate our commitment to quality. Additionally, we continuously invest in the introduction of advanced equipment from domestic and foreign sources, and employ skilled technical and quality inspection personnel to maintain high levels of quality throughout the production process.

Business Guidance

We design the process according to your product and drawings to help you get the maximum benefit with the minimum production cost

Professional Production

We have independent mold production department and professional R & D team, so OEM and customization service is our specialty. We have professional R & D team and quality control personnel. Each production process has strict technical requirements

Quality Control

Each production process has strict technological requirements, all departments cooperate with each other, strictly control each part of production, to achieve efficient and high quality delivery. Can control the quality of products at the same time to provide quality service

Perfect Logistics

Located in Ningbo Yinzhou District, less than 50km away from The world’s fourth largest port: Ningbo Beilun Port. Work with selected logistics companies can save a lot of delivery time and transportation costs

After Sale Service

We don’t want to be your passer-by, we want to be your life-time partner! We will accept our responsibility and do our best to help you solve the problems

Market Analysis

We will analyze the different conditions of each region regularly and give professional advice according to your local market conditions for your reference. At the same time, we will recommend new product lines according to your industry and market positioning

Special Fastener Customization Capabilities

With our extensive product range and in-house manufacturing capabilities, we are equipped to fulfill your every requirement

from traditional craftsmanship to cutting-edge technologies such as cold forming, precision CNC machining, and stamping

Cold Forming Parts

Machining Parts

Stamping Parts

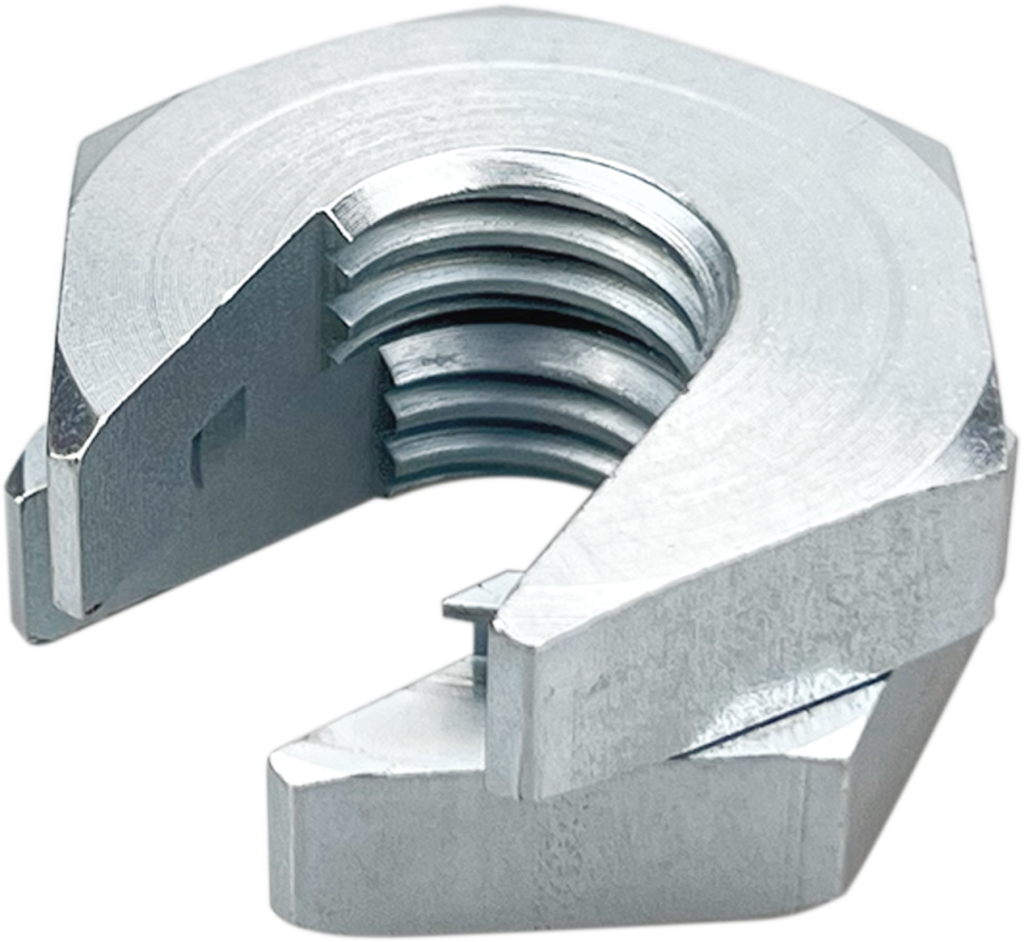

Slip-on Lock Nuts

Avoid time consuming winding & unwinding on long threads and overcome issues of damaging threads.

The slip-on lock nut is easy to position at any point on a thread. Just open the lock nut, position where required, twist the lock nut closed and tighten with a spanner.

Application Field

Our products are widely used in machinery, automobiles, ships, chemicals, industrial and mining railways, engineering, bridges, electronics, furniture and sports equipment, and are involved in aerospace, land and sea transportation, electric tools, hand tools, auto and motorcycle accessories, kitchen and household appliances and other fields.

Credibility Is Our Purpose, Service Is Our Goal!

We are confident that the fine quality and reasonable price will bring you high economic benefits

We’d like to sincerely cooperate with enterprises and build a long relationship to create a splendid future together